-

CNC Precision Machining

-

Stainless Steel CNC Machining Services

-

Magnesium Precision Machining

-

Titanium CNC Machining

-

Low Volume CNC Machining

-

Sheet Metal Fabrication Service

-

CNC Milling Service

-

5 Axis CNC Machining Services

-

Plastic Injection Molding Service

-

CNC Turning Service

-

Die Casting Service

-

Vacuum Casting Rapid Prototyping

-

Custom 3D Printing Services

-

David WyameI worked with JYH for many years and They help me doing some high precision metal parts,it is really good and high tolerance.

David WyameI worked with JYH for many years and They help me doing some high precision metal parts,it is really good and high tolerance. -

Brian“JYH not only committed to manufacturing all of our parts with only minor adjustments but also offered competitive costs that fit within our budget, all while ensuring strict adherence to our tight timelines. “ DOM BU

Brian“JYH not only committed to manufacturing all of our parts with only minor adjustments but also offered competitive costs that fit within our budget, all while ensuring strict adherence to our tight timelines. “ DOM BU -

Rabiul“JYH fully meets our demands and construction requirements. Its staff has the skills to understand and satisfy the demand for very complex designs to micro-machining. In addition, the delivery time is very fast. This is very important to us as we make “Build on order” devices.” – OPEN

Rabiul“JYH fully meets our demands and construction requirements. Its staff has the skills to understand and satisfy the demand for very complex designs to micro-machining. In addition, the delivery time is very fast. This is very important to us as we make “Build on order” devices.” – OPEN

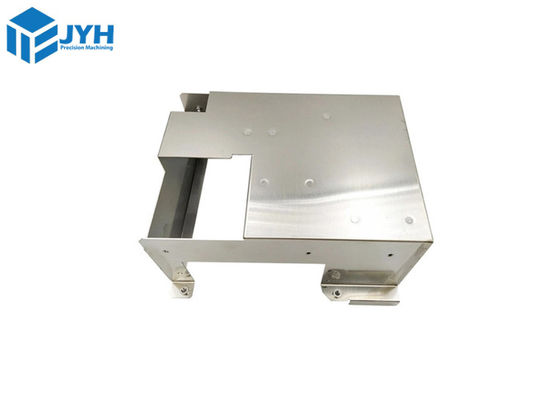

Advanced Sheet Metal Fabrication , Precision Prototype Sheet Metal Parts

| Place of Origin | China |

|---|---|

| Brand Name | Auto sheet metal fabrication |

| Certification | ISO9001 Certificate of quality system/16949 |

| Model Number | SPCC,SHCC ,SECC ,SGCC |

| Minimum Order Quantity | 1 piece |

| Price | USD 20-100 pieces,negotiable |

| Packaging Details | Use boxes made of corrugated cardboard,Wrap with bubbles facing inward or Custom wooden cases larger than 25KG. |

| Delivery Time | 5-8 works day |

| Payment Terms | T/T, Western Union,Paypal |

| Supply Ability | 1000 piecs one weeks |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Advanced Sheet Metal Fabrication | Thickness Wall | 0.5-10mm,Can Negoation With You |

|---|---|---|---|

| Structure And Size | It Can Be Customized | Processing Way | Advanced Sheet Metal Fabrication |

| Tolerance | ±0.05mm, Based On Your 2D Drawings | Sheet Material | SPCC,SECC , Al 5052 , SS316 / SS304 |

| Surface Treatment | Powder Coating , Zinc Plating , Nickel Plating , Painting And So On | Welding Method | Spot Welding/full Welding |

| High Light | Precision Prototype Sheet Metal Parts,Advanced Sheet Metal Fabrication Parts,ISO9001 Advanced Sheet Metal Fabrication |

||

Advanced Sheet Metal Fabrication , Precision Prototype Sheet Metal Parts

JYH Precision Sheet Metal Fabrication Service

5-10 day lead time•200+ engineers served•8 thousand parts delivered

Sheet metal fabrication is the most cost-effective choice for custom sheet metal parts and prototypes with uniform wall thickness.

Custom engineering and manufacturing services from prototypes to on demand production of sheet metal parts. Low-cost sheet metal fabrication solution for you.Dedicated JYH’s team to ensure your parts consistently meet your quality expectations. We also offer phone, email and chat support for any concerns or questions you may have.

- ISO 9001: 2016

- Fast delivery service with DHL/FEDEX/UPS

- Standard-DIN-2768-1-fine

- Free quotation with DFM review in 1 hours

- Deburr all sharp edges: 0.1 - 0.2 mm

- Surface roughness: Ra 1.6

JYH Precision Quality assurance

Our unwavering commitment to product quality assurance in sheet metal fabrication is evident in every aspect of our process.

Our ISO 9001:2015, ISO 13485, and AS9100D certifications reinforce our commitment to maintaining the highest standards.

![]()

JYH Precision Available materials for sheet metal:

Below is a list of our standard available metals for sheet metal fabrication

|

|

|

|

|

| 5052/6061 | 304/316 | 1018 | C110 |

JYH Precision Tolerances for sheet metal fabrication

The table below summarizes the standard tolerances of the parts produced by JYH’s Manufacturing.

| Feature | Tolerance |

| Cutting feature | ± .00787’’ (0.2 mm) |

| Bend angle | ± 1.0° |

| Bend to edge | +/- 0.010’’ (0.254mm) |

JYH Precision surface finishes for sheet metal

Surface finishes are applied after machining and can change the appearance, surface roughness, hardness and chemical resistance of the produced parts.

|

|

|

|

|

|

Standard surface finish |

This is our standard finish. Parts as delivered as cut and bent, no additional treatment applied. Sharp edges are broken and deburred for safe handling. |

| Brushed | Parts are manually brushed with grit #180 after cutting and bending. Sharp edges are broken and deburred for safe handling. Ideal to reduce the surface roughness of a part. | |

| Brused + Anodized type II | Parts are dipped in an anodizing bath (type II) after manual brushing. Ideal for increasing the corrosion resistance of the part. Ideal for increasing the corrosion resistance of the part. | |

| Powder coating | Powder coating layer is applied directly after fabrication. Sharp edges are broken and deburred for safe handling. | |

| Black oxidization | Parts are dipped in a black oxide bath after fabrication. Ideal to improve improve corrosion resistance and minimize light reflection in steel components. |

Available sheet metal fabrication processes

Gives you easy access to sheet metal fabrication capabilities to serve all your manufacturing needs.

| Name | Description | Allowable sheet thickness |

| Laser cutting | This manufacturing process uses a high-power laser beam to cut a material sheet. | 1-6mm(depending on material) |

| Bending | This manufacturing process uses dies to produce a U-shape,V- shape or channel shape along a straight axis in ductile materials | 1-8mm (depending on material) |

JYH Precision Shipping way

![]()

JYH Precision Payment method

![]()

JYH Package way

![]()

Our workshop:

![]()

![]()

FAQ

1. What are the tolerances for fabricated parts?

Sheet metal fabrication tolerances refer to the acceptable deviations for features of sheet metal parts required for accurate and consistent installation and integration.For sheet metal parts, ISO 2768-mk is usually used to ensure proper control of the elements of geometry and size.

The following will show you 7 tolerance standards range of linear and angular dimensions, flatness & straightness, cylindricity, and circularity.

2. How much does sheet metal fabrication cost?

Every aspect of a sheet metal fabrication project comes with an associated cost — the design, possible prototype, finishing processes, and others. Asides from the process itself, materials also cost money.

3.Whatis the lead time for our project?

It need to based on your product's size and QTY/Structure.

JYH is your best partner of Sheet Metal Enclosure Fabrication And Production Stainless Steel Sheet Parts!